Customer-Specific Warehouse Management

There are many options out there in terms of Warehouse Management systems – which to choose? Not every solution is a one-size-fits-all, which can make the process of making the switch to automated storage a difficult one.

Thankfully, there are companies out there that prioritise catering specifically to their customers’ needs. Meet STOPA.

A German company with its headquarters in Achern, STOPA is changing the face of warehouse management with its innovative storage solutions.

Though they showcase a wide range of different storage solutions, for sheet metal and bar storage STOPA like to encourage individuality and are more than happy to produce custom solutions for their customers.

Such is the case with one such customer – Aesculap AG.

STOPA Compact Series, which Aesculap invested in

Encouraging Individuality: A Customer Profile

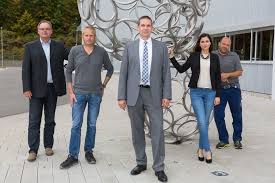

Aesculap, the 2nd largest division of B. Braun Melsungen AG, is a medical equipment manufacturer based in Tuttlingen, Germany. With a workforce of over 200 employees, things are always busy!

The company manufacture their products over two floors – on the ground floor aluminium and stainless steel containers are produced, and on the first floor they manufacture goods specific to surgical interventions.

The team at Aesculap, L-to-R: Joachim Bludau Head of the Sheet Metal segment, Gerald Reischmann Production Planner, Nadine Weckenmann Project Manager, and Volker Huber Head of the Sheet Separation Group.

Aesculap wanted to create an Innovation Factory, in which they would place special focus on structural and technical flexibility as well as energy efficiency.

Before investing in the automatic sheet metal storage system provided by STOPA, Aesculap had stocked the raw material in premises separated from the production facility, thus giving rise to considerable logistical effort and expense.

“Our wish list included… a controlled material flow, direct access capabilities to the raw material and greatly reduced non-productive times. However our main requirement related to the customer-specific orientation of the warehouse management system”, says Joachim Bludau, head of the Sheet Metal Segment in the Motors and Containers.

In response to Aesculap’s needs, extensive modifications were made to STOPA WMS-Extended, whose basic functions include stock and storage location management and the provisioning of the processing machines with material. Thus, on each input of sheets requiring batch handling, WMS-Extended checks whether the operator is storing the relevant sheets on the intended pallets.

Before the start of the job, the system calculates the required quantity of raw materials. If the material present if not sufficient then the job is not started and the employee is informed of this.

The Result

In addition to the basic functions, the STOPA WMS Extended warehouse management system has been tailored to meet Aesculap’s customer-specific needs, including:

- A check of the correct storage of every input of sheets requiring batch handling.

- Calculation of the required raw material quantities before each job is started.

- Plausibility checks, including the measured weight, on storage and removal operations.

- Management of a consignment store, a separate leftover sheet store, as well as locked stocks, which include all newly stored materials up to the point at which they have been checked and approved.

- Storage close to where sheet processing takes place, with the ‘preferred machine’ ID.

The STOPA Storage Range

Take a look at the full range of STOPA storage solutions available below: